Anti-earthquake Technology

- Seismic diagnosis and reinforcement method

- 3Q-Wall Method, 3Q-Brace Method

- Steel Pipe Fixing Method (Steel Pipe Cotter Method)

Seismic diagnosis and reinforcement method

Japan is said to have entered a period of seismic activity. In order to protect safety, assets and daily life, Daisue has been proactively proposing seismic diagnosis and reinforcement work. Since the Great Hanshin-Awaji Earthquake and the Great East Japan Earthquake, following government initiatives, we have received many inquiries and have been carrying out seismic diagnosis and strengthening work.

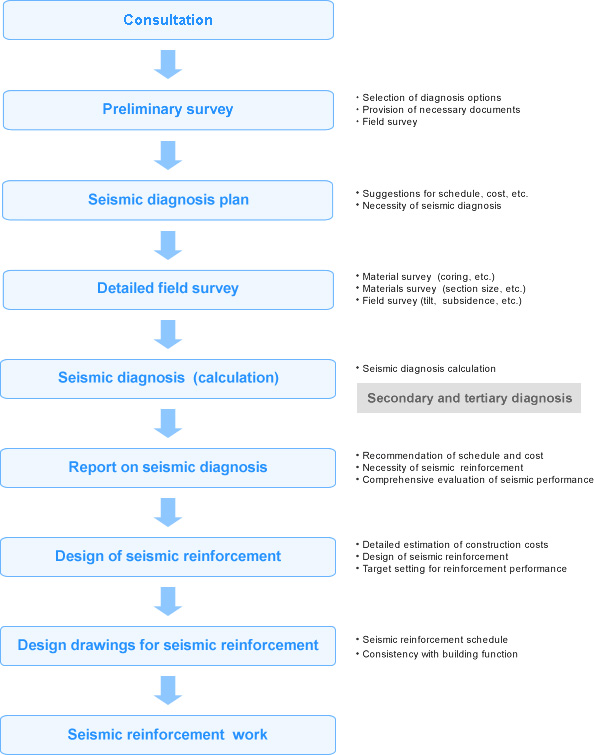

Workflow from seismic diagnosis to seismic reinforcement construction work

3Q-Wall Method, 3Q-Brace Method

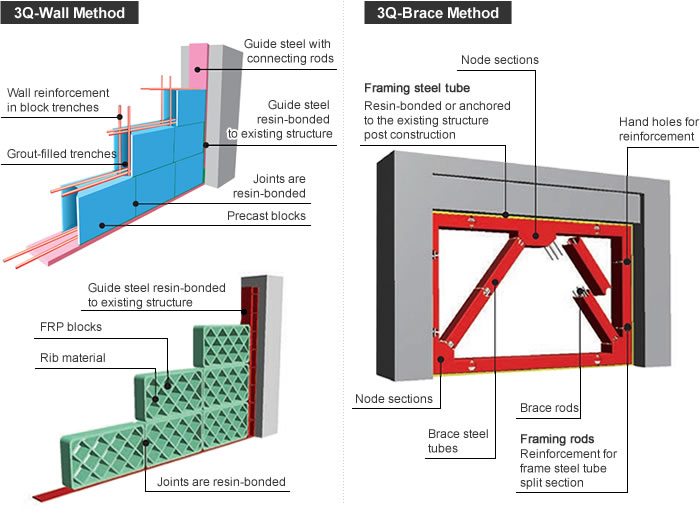

3Q-Wall is a seismic reinforcement wall that was developed to reduce noise and vibration during reinforcement work and to shorten the construction period. In this method, small blocks are assembled to form a seismic reinforcement wall that is firmly bonded to the existing structure. Three types of walls are available: new walls consisting of precast blocks, additional walls and wing walls; new walls consisting of FRP blocks; and new walls consisting of precast blocks and FRP blocks. The most suitable form is proposed according to the required load-bearing capacity and design.

3Q-Brace is a brace reinforcement system in which lightweight thin-walled steel tubes are divided into sections, assembled into braces, reinforced with steel bars and filled with grout. There is no need to weld or bolt the steel tubes to each other, thus saving space and avoiding the use of open flames. The steel tubes also act as mortar restraints and formwork, making it possible to provide steadfast reinforcement and reduce construction time and labor.

The method has been certified by Obayashi Corporation in accordance with the Building Technology Performance Certificate (Performance Certificate No. 02-06, Revision 5) of the General Building Research Corporation of Japan.

In July 2009, it was further certified as suitable for reinforcing existing low strength concrete frames and thickening mortar walls.

For more information, please refer to the 3Q-Wall Method Study Group's website.

Steel Pipe Fixing Method (Steel Pipe Cotter Method)

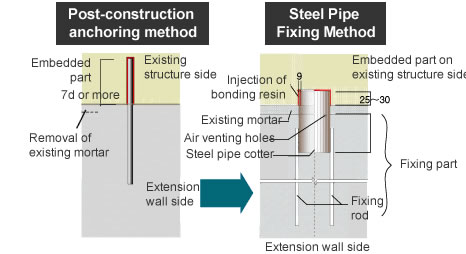

The "Steel Pipe Fixing Method" has replaced the post-construction anchors used in many seismic reinforcement projects. It involves digging a cylindrical trench in the cover of an existing structure, inserting a steel pipe, and then fixing it by resin bonding. In recent years, there has been a rapidly increasing demand for seismic reinforcement works that can be carried out while the building occupants continue to work, without needing to relocate during the construction work. The steel pipe fixing method has less impact in terms of noise, vibration and dust, and can be applied to all types of buildings for seismic retrofitting, making it possible to carry out seismic reinforcement work safely, with high quality and at low cost without the need for building occupants to relocate.

This method was certified by the General Building Research Corporation of Japan on October 8, 2010 (Building Technology Performance Certificate GBRC 03-04 Revision 4).

For more information, please refer to the website of the Steel Pipe Cotter Method Research Group.

Japanese

Japanese Contact Us

Contact Us