Construction Technology

Industrialized Method

Buildings are made up of columns, beams, floors, and walls. In the industrialized method of construction, these components are divided into their respective elements and made into factory products (PCa components) whenever possible, which are then delivered to the construction site and assembled.

Daisue has been actively involved in industrialized construction methods from the earliest days, accumulating skills and knowledge and establishing an endless number of case studies.

Generally speaking, the industrialized construction method requires a worksite where large cranes can be installed. In order to make the advantages of the industrialized construction method even more effective, we are working on the development of PCa at the tip of the balcony PCa with the aim of extending it to construction work in urban areas where large cranes cannot be installed.

Pile Drop Method

The cutting work after extra fill for settlement of cast-in-place concrete piles generates a lot of noise and vibration. This has been a problem in urban areas. As a countermeasure against this noise and vibration in urban areas, Daisue has developed a new method to achieve low noise and vibration, shorten the construction cycle, and reduce costs by greatly reducing cutting work while maintaining the quality of the pile head.

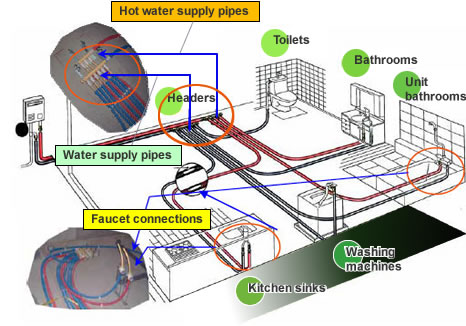

Prefabricated Header Method

This is a water supply and hot water piping system in which all pipes and headers from the meter box to the faucets in the condominium are prefabricated at the factory and then transported to the site for installation.

The pipes are made of polybutene, and the joints are also made of resin and thermally bonded at the factory. There are two main types of piping systems for water supply and hot water supply: the "pre-branching method" and the "conduit pipe header method." The "pre-branching method" involves branching with elbows or cheese, etc. according to the required location, while the "conduit pipe header method" involves installing a header around the water heater or pipe shaft and threading resin pipes through conduit pipes, which are laid in an octopus shape from the header to each water faucet. In the existing "conduit pipe header method," when factory-made conduit pipe headers are installed in the field, the length of pipe to the faucet often does not match the pipe drawing.

The "prefabricated header method" solves this problem by using our construction know-how to freely adjust the length of the pipe to the faucet so that it can be installed correctly even if there is a discrepancy with the drawing. In addition, the number of connection points is reduced compared to the "pre-branching method" and the risk of leakage is greatly reduced.

We hold a joint patent with Saicho Bussan for this method.

Japanese

Japanese Contact Us

Contact Us