Structural Technology

- Seismic Isolation Construction Method

- High-rise RC Structures

- RCS Hybrid Construction Method

- CFT structures

- MAX-E Method (Beam End Opening Reinforcement)

Seismic Isolation Construction Method

Daisue's seismic isolation construction method dampens the vibration of earthquakes by installing a specially structured seismic isolator on the foundation, thereby ensuring the internal stability of the building. This method has been widely used in office buildings, condominiums, hotels, museums, hospitals, research facilities, and computer centers, etc., resulting in almost no damage during the Great Hanshin-Awaji Earthquake, the Great East Japan Earthquake and other magnitude 7 earthquakes.

High-rise RC Structures

This construction method is used for high-rise buildings over 60 meters in height, using high-strength concrete and high-strength steel reinforcement instead of a traditional SRC structure. It is an RC construction method that uses a pure Rahmen structure for the beams and girders in both directions. These high strength materials are used to build high quality structures to provide a safe and reliable building. In some cases, we use prefabricated columns, beams and floors to simplify the construction process, shorten the construction cycle, and improve quality.

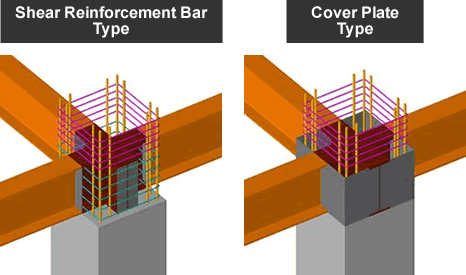

RCS Hybrid Construction Method

The RCS Hybrid Construction Method consists of reinforced concrete columns and steel beams. Steel frame construction is usually used for buildings with high floors and large span structures, but this approach is costly for warehouses and other buildings with large load-bearing capacity. The RCS Hybrid Construction Method is a cost-effective hybrid structure that combines the advantages of load-bearing reinforced concrete columns with steel beams for large-span structures.

The RCS Construction Method was jointly developed by the RCS Hybrid Construction Method Research Group (Note 1).

Note 1: Asunaro Aoki Construction, Asanuma Corporation, Okumura Corporation, Seibu Construction, Daisue Construction, TOA Corporation, Nishimatsu Construction, Hazama Corporation, Haseko Corporation

We have been awarded the Building Technology Performance Certificate by the General Building Research Corporation of Japan.

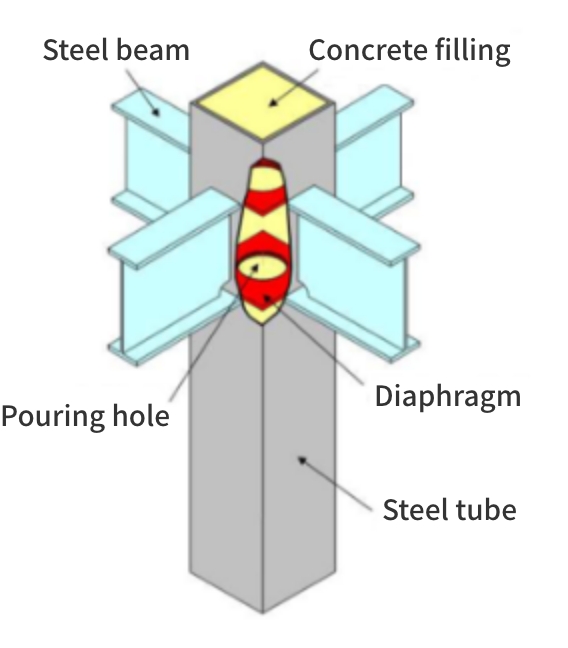

Concrete-filled steel tube (CFT)

What is a CFT structure?

Concrete-filled steel tube (CFT) structures combine steel beams and other components with round or square concrete-filled steel tubes. By filling steel tubes with concrete, it is possible to leverage synergistic effects that exceed the characteristics of either of the two materials alone. CFT is attracting attention as the fourth in a series of other structural techniques: reinforced concrete, steel-framed reinforced concrete, and steel framing.

Comparison of CFT with other structures (CFT structure characteristics)

| Comparison with steel-framed structures |

|

|---|---|

| Comparison with reinforced concrete and steel-framed reinforced concrete structures |

|

Technological classification of CFT structures under a construction technology ranking program

Daisue Construction has earned technological rank certification under a CFT structure construction ranking program administered by the Association of New Urban Housing Technology.

MAX-E Method (Beam End Opening Reinforcement)

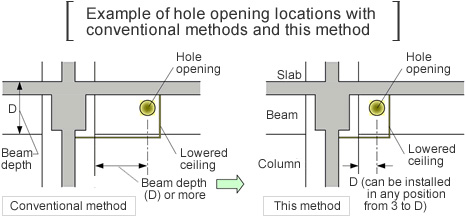

The MAX-E Method is a reinforcement method and design method that ensures the required structural performance of reinforced concrete beam ends even when holes for equipment and pipes are provided, something that was impossible with previous techniques. In residential buildings, it is common to install through holes in beams due to floor height restrictions and the need for ventilation systems. In residential projects, there are many requests for openings at the end of beams for equipment and ducts, but beam-end openings have been avoided from the point of view of ensuring structural performance. To solve this problem, we developed an opening reinforcement method that allows holes to be opened at the ends of beams.

Beam End Opening Reinforcement Study Group (consisting of 10 companies, 9 general contractors including us and 1 manufacturer)

We have been awarded the Building Technology Performance Certificate by the General Building Research Corporation of Japan.

Japanese

Japanese Contact Us

Contact Us